Pellet machines are the new way to do business in the 21st century. They are more efficient, environmentally friendly, and cost-effective than any other equipment you’ve ever used. These machines will revolutionize how you view your business and how it operates. They will change everything from your fuel costs to your labor budgeting. Plus, these machines are so easy to use! In this post, you’ll learn about what a pellet machine is and why it is going to change everything for businesses large and small across the world. We will also discuss how does this machine work? how much does it cost? its benefits, and how it could save our environment.

What Is Pellet Machine?

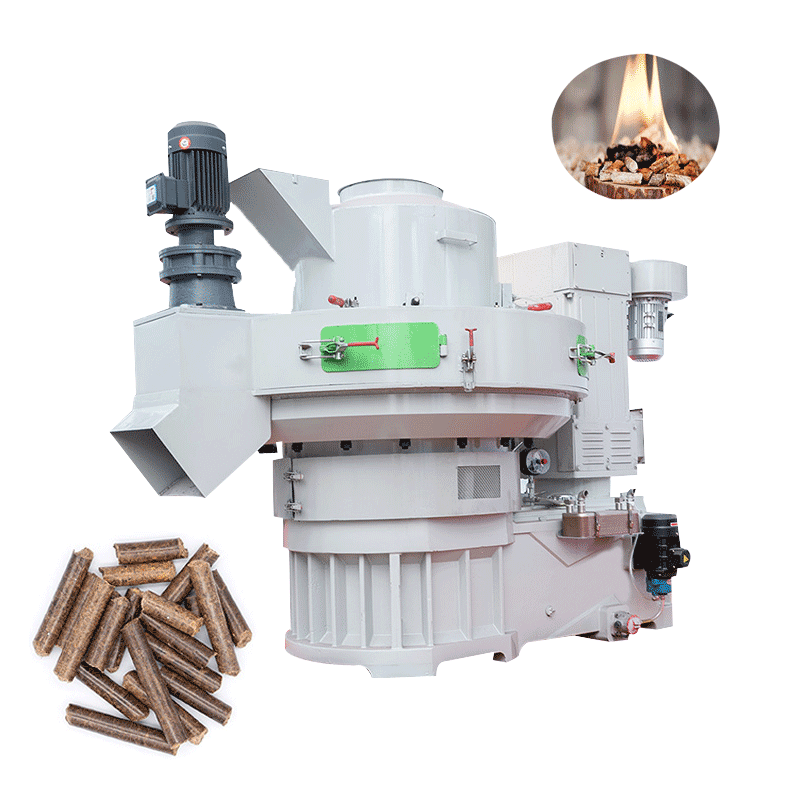

Pellet machines are the equipment used for making pellets of different shapes and sizes. Pellets are a compressed form of fuel. They are an alternative to coal, wood, or plastic pellets, the three common fuels used in pellet stoves. The materials can be any combination of sawdust, recycled paper, cardboard, or sawdust and soybean oil. The machine can produce energy-rich fuel at a lower cost than traditional fuels like coal.

Pellet Machine Types

Pellet mills come in two distinct varieties: flat die and ring die.

- The flat die pellet mill is the simplest type of mill. With this type of machine, the feedstock is crushed by heavy steel rollers in a rectangular plate with a hole in it. The rollers rotate around a fixed horizontal axis and the product exits from the hole in the plate.

- The ring dies pellet mill is more complex than a flat die pellet mill and this type requires additional components such as an aeration system, heating system, and cooling system to produce pellets.

With both types of mills, there are two ways to process materials: wet or dry. Wet processing involves adding water to ground-up feedstock at the start of production while dry means there is no water added at any point during production.

Pellet Machine Functions And Its Benefits

Pellets are used in many industries as a fuel source, such as power plants, cement factories, and paper mills.

The pellet machine functions by taking a material (typically wood chips) and using heat to turn it into uniform pellets. Pellets are then cooled in water before being packaged for use. It basically heats up the feedstock to a certain degree for the different types of pellets depending on the requirement. The other thing it does is control and monitor temperatures and pressure levels within the pellet machine as well as keep track of what’s going on with inventory.

It also has a computer interface that allows inputting information like temperature and pressure values, fuel levels, etc in order to provide accurate data on these readings such as their exact level or grade.

One of the many benefits of a pellet machine is that it is able to produce pellets from any type of feedstock. There are many benefits to using a pellet machine for this process, including the following:

- Efficiently uses energy– A pellet machine can efficiently use natural resources like coal, firewood, and biomass to produce heat. It is a very efficient way of using these sources to create heat.

- Produces less waste than other methods–

A major benefit to using a pellet machine is that it produces less waste than other methods. For example, with a pellet machine, you can produce around 20,000 pellets per hour. This is also beneficial for the environment because it will reduce the carbon footprint by over 80 percent and it can produce energy in order to heat up water so that you don’t have to use an additional source of fuel or electricity. - Reduces the cost of transportation– Pellet machines can reduce the cost of transportation significantly. In the past, the entire operation relied on a single provider who had to deliver hay from the field to feedlots. It was expensive and inefficient because it was so time-consuming. With pellet machines, farmers can produce their own feed themselves, and therefore need less transportation than before when they had to rely on suppliers for hay.

- Produces more uniform pellets than other methods– A pellet machine makes it easier to produce more uniform pellets than other methods, like extrusion.

Producing pellets is a time-consuming job that can be difficult for one person to do. That’s why a pellet machine is more efficient because it can provide high performance and require less operator attention.

The greater the number of machines, the less time will be needed for production, which will increase productivity for the company.

The pellet machine offers an abundance of benefits that help provide increased business value and increased profits by using fewer labor hours. The company also has an opportunity to reduce costs by purchasing equipment in bulk quantities and increase profit margins by selling surplus energy created from processing corn into products such as ethanol or animal feed.

Pellet Machine Cost

The pellet machine, also called a pellet mill, is a machine that processes wood pellets into the form of customized pellets. The price of the pellet machine varies depending on the features and brand.

The cost of a typical pellet mill ranges from $10,000 to $50,000. However, this price can change depending on what you are looking for in your milling needs. If you need a customized feature that is not present in a standard-model machine, be prepared to pay more for it.

A lot of people have asked me where they can buy this type of equipment because they are interested in buying one for their home or their business. There are multiple places to find a pellet machine for sales like online auction sites or classified ads.

What to Look For In A Pellets Machinery When Buying One

Pellets mills are a key part of the biomass industry. They are used to make pellets from wood chips, sawdust, and other plant-based materials.

When buying new pellet machinery, it is important to choose a manufacturer who is reliable and will provide quality products. Good quality pellet machinery should have a low carbon footprint. The cost of operation for the machinery should also be considered when making an investment in buying a new pellet mill. A good quality machine will produce pellets with less dust content and have an easy maintenance process that requires little to no oversight.

Conclusion

The only thing that has slowed down the progress of pellet machine adoption is the increase in competition. As more people are seeing their benefits, more and more manufacturers are coming up with similar products and services.

In this article, we looked at the effects of pellet machines on our environment and also how they can help us to do our part for a greener planet.

We have also seen how pellets can be used for things other than making electricity. For example, some people use them as animal feed or as a renewable fuel in industrial applications.